Eddy current is a very efficient tool for many NDT inspection tasks. As long as the object to be tested is electrically-conductive, a surprisingly extensive range of inspections can be carried out. And this without damage or permanent material modification.

How does it work?

The eddy current technology could be utilized quite effective for many different tasks in the world od non-destructive testing. Eddy current inspections is based on the principle of electro-magnetic induction. The use and know-ledge of the electrically and magnetically effects and their resulting eddy currents reveals many different property changes of the inspected objects.

ec-works provides:

Our in-house developed documentation-software for the interpretation and evaluation of eddy current signals includes a feature toconvert files into different software formats like the CAD format dxf format or the common pdf-Format. This makes our documentation results easily legible for our clients, making the acquisition and installation of special software for the review and use of our documentation unnecessary.

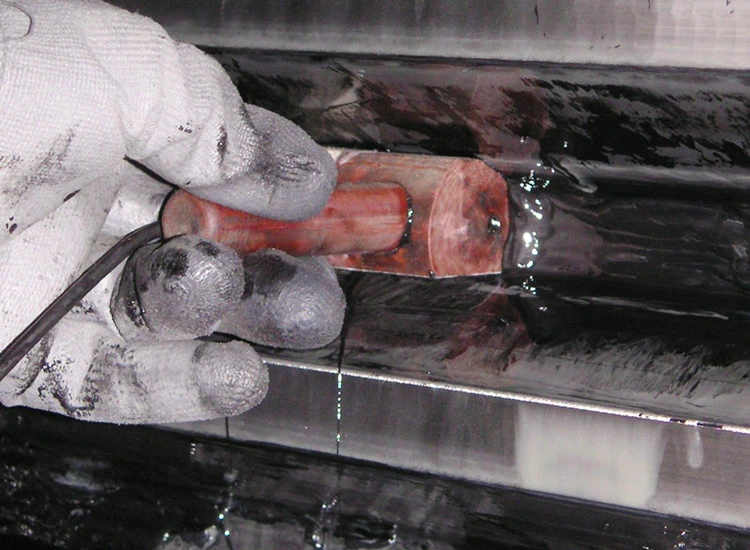

The focal point of our research and development is the enhancement and adaptation of our eddy current probes, the inspection sensors that allows us to look into the inspection objects.

Each probe is individually adapted to the specific inspection tasks of our clients and tested on-site by our eddy current experts. Our company structure and corporate philosophy are the key factors for our strong eddy current service capabilities.

Let discuss your eddy current inspection task. Please ask your question, there is no “stupid” question in the world of NDT. Enter your task / need here: Ask

Our personal involvement, reliable technical consultation and flexible realization are our basic steps to guarantee your satisfaction.